2018 Fall Semester Progress (Test Rigs pt. 1)

- BLUElab Thailand

- Feb 2, 2019

- 2 min read

Hello, I’m Allison, one of the Project Leaders for this school year! (For those who may be just joining us, I encourage you to follow our Facebook or check in “Current Project” for updates, but I’ll be taking time to showcase what the BLUElab Thailand Team has been up to for the past 4 months. A comprehensive Fall 2018 Activities Report can be found here.)

After September, we spent a few meetings for Team Objectives and Team History to onboard our new members. They have brought an incredible enthusiasm and creativity towards the team and project, allowing for Finance Team to immediately tackle grant-writing and team social initiatives (including a Thai Movie Night). A member conducted Value Committee Workshops about BLUElab’s values, and we also learned to prototype early and often with help from C-SED (Center for Socially Engaged Design) at UMich.

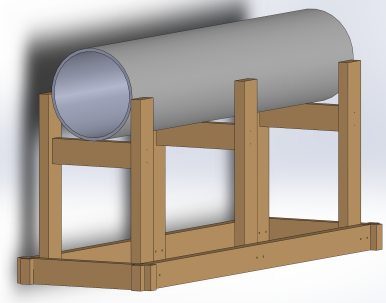

At this point in our flood mitigation project, we are at a point where information we’ve gathered about our project location and scope must be translated into physical concepts and prototypes that can be presented to the user and tested. After this summer, we aim to improve and iterate upon our prototype for Need 2, generate a new prototype for Need 1, and construct a test rig of the Mae Chan drainage system to test our prototypes.

After consulting university supporters and faculty, we identified that building a test rig that simulates our working environment allowed for prototype validation (predictive field performance and justification for design choices) and allow our Engineering team to develop a familiarization of the environment while honing their manufacturing abilities. Consequently, our Design Teams split into two sub teams:

1) A way to control water flow through 11 key drainage points in Mae Chan City

2) A way to clear debris and sediment inside the pipes.

Our design team looked conducted Tech Reviews of Existing Technology/Test Benches before researching materials (including Home Depot Trips) and formulating designs.

After our members taught each other CAD, we iterated from these ideas…

to these!

By January, our design team executed their Manufacturing Plans in a stunning 2 days.

Head on over to our next blog to see the final product!

Thanks for following along!

-Allison

Comments